Biodiesel

The History

The first diesel engine was invented by Rudolph Diesel in 1893. Although the diesel engine was capable of running a wide variety of fuels, the first diesel engine ran solely on peanut oil. Rudolph Diesel’s vision was for farmers to have the ability to fuel their equipment with the vegetable oils that they produced themselves.

Throughout the 20th century, many countries experimented with vegetable oil as fuel for combustion engines, though unrefined vegetable oil proved to have more operational problems than petroleum based diesel. Many improvements were made in the vegetable oil refining process, until the first account of biodiesel production (also known as transesterification or alcoholysis) was reported in 1937 by G. Chavanne at the University of Belgium in Brussels.

The first industrial scale biodiesel production facility was erected by an Austrian company in 1989, and plants have continued to open throughout Europe, North and South America, and Africa. In 2011, world biodiesel production reached 1 billion gallons, and has continued to increase each year. Biodiesel is available throughout the United States and numerous major engine companies have approved its use in many of their vehicles.

The Industry

Currently there are 2.4 billion gallons of biodiesel produced by registered facilities, and available in at least 2,000 public locations nationwide. The industry has a projected a 4-Billion gallon production goal for 2022. Iowa is the leading producer of biodiesel due to the state policies plus their Iowa Renewable Fuels Infrastructure Program. This program helps fuel distributors and retailers upgrade their equipment so they can include biofuels; in doing so this has resulted in 261 new biodiesel retail pumps and 55 terminal locations throughout Iowa since 2006. According to the National Biodiesel Board in 2016 Iowa’s biodiesel plants set a record for 305 million gallons produced.

Benefits of Biodiesel

-

Keeps fuel a domestic and sustainable resource

-

Supports about 62,000 jobs

-

$17 billion generated in total economic activity for 2015

-

Better for the environment

-

Uses renewable resources such as byproduct for production instead of sacrificing food

-

The soy protein meal price has decreased $20-$40 per ton due to the creation of market and value for excess soy bean oil, which is used to produce Biodiesel.

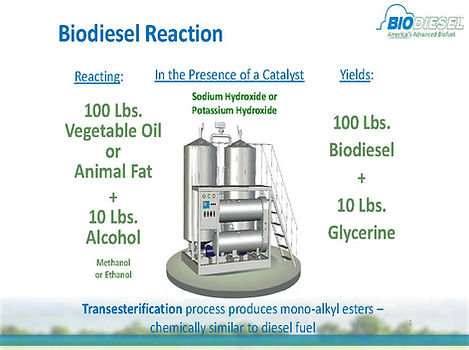

The Process

The process of producing biodiesel is called esterification or transesterification. The three key components to biodiesel production are vegetable oil, alcohol, and a catalyst. When these components are combined in the proper proportions, transesterification occurs, or the separation of methyl esters from glycerin molecules. The glycerin is then removed from the esters, and the esters are then washed, dried, and filtered to create biodiesel. Biodiesel can be produced from a wide range of vegetable oil. Common feedstock in biodiesel production includes soybean oil, corn oil, recycled cooking oil and palm oil. Products of the reaction include not only biodiesel, but also co-products such as soap, glycerin, excess alcohol, and trace amounts of water. Glycerin from biodiesel production can be further refined, and has countless food, cosmetic and industrial applications.